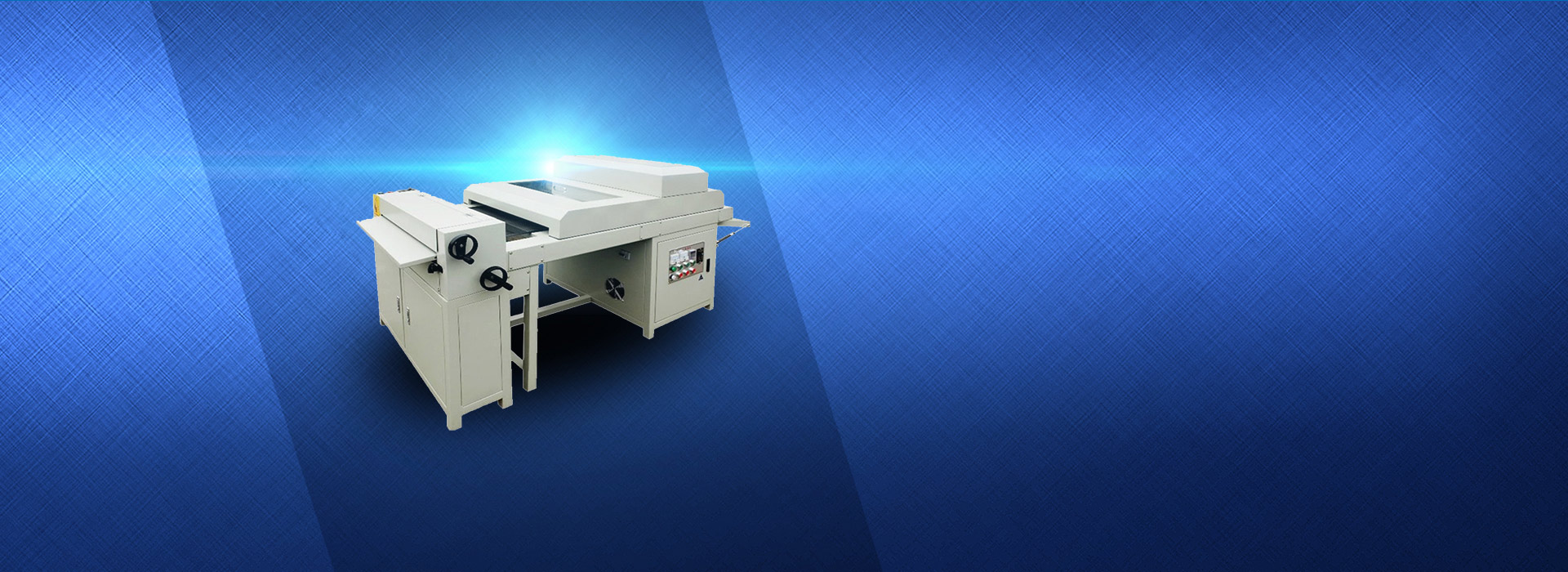

Wood Edge polishing and gilding machine

Model | GS-PGWOOD |

Max. gilding width (mm) | can be adjust |

Max.Gilding temperature (℃) | 150 |

Max. gilding thickness (mm) | 5-30 |

Max. gilding speed (mm) | 2-5m / min |

Power rating(KW) | 4.2 |

Air compressor | 8mpa |

Packing dimensions(mm) | 2030x940x1210 |

Weight (kg) | 450 |

Power supply | 220V\50Hz |

1. Three in one function : trimming machine, grinding machine, hot edge machine, simple operation, 100% qualified.

2. Save labor: one operation, eliminating the 1-2 artificial, four months but can save the machine investment.

3. Save time: four processes once completed, eliminating more than 70% of the time, efficiency greatly improved, especially for high-volume operation. One day can produce about 1000 frames without frame.

4. Transmission part of the low-speed motor, chain drive, no wear and tear, long life, easy to replace parts.

5. With a spindle motor with high-speed running trimmer alloy knife and two polished electric running polishing wheels. It automatically enters the hot side system consisting of a paper feed wheel and a paper feeding roller. Machine fully realize the real human nature of the automatic assembly line operating procedures.

6. Truly fully automated control, the latest digital frequency converter also added, can automatically control the speed of repair grinding

7. Trimming knife angle and the level of hot stamping can be adjusted freely, for a wide range, the use of value

8. Bronzing speed, the machine uses squirrel-cage lines, integrated control, fully automatic grinding burn once completed, the security is quite high

9. A multi-purpose machine, in addition to the wooden plate can also be heated to repair the edge of the resin crystal side trim polished

10. The machine has the unique automatic thickness protection device and the wood plate width telescopic support platform, the operation is more at ease

11. Machine design novel and unique, convenient and practical: just stick a good photo of the MDF into the machine's trajectory, it will automatically complete the first oblique and then polished, and then straight edge grinding and polishing.

12. And then track the process of running automatically hot side, compared to the manual hot-side machine yield is not only 100% but the important thing is hot was too hot firmly in prison.

13. Machine maintenance is very convenient and practical, trimming knife and polishing wheel,bronzing wheel adjustment and replacement can be completed a few minutes, user-friendly design

中文

中文 English

English